Installation of stainless steel panel tank is quite easy and takes very less time if the procedure is followed correctly. So in today's blog we will be discussing the major points to keep in mind before doing installation.

Please follow the below instructions to make your panel tank installation hassle free.

Caution for Crane operation, Installation & Plumbing.

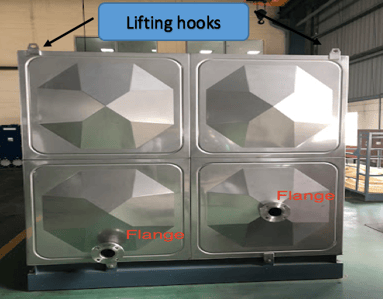

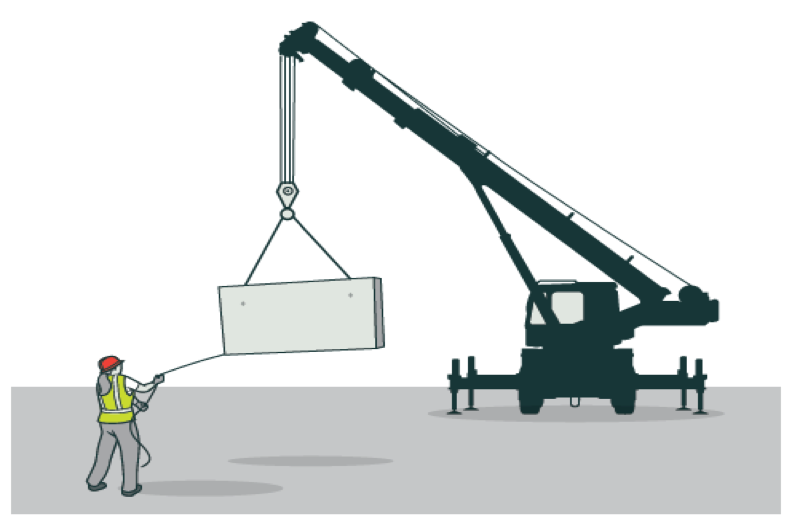

1. Crane Operation

- Each hook has to be hanged under equal loading.

- Hanging with rope have to be an angle of 60 degree.

2. Installation

- Do not apply concentrated load and impact load locally.

- Free up space with over 60cm around the tank and over 100cm on the top of the tank for maintenance operation after installation.

- Do not use the tank as a foothold.

- Take precaution when you work around the tank especially weld, cutoff & grinder operation to avoid attached iron powder, rust and scratch.

3. Plumbing

- Have to set the flexible joint between connection port of the tank and each pipe to protect from the earthquake and vibration by other equipment.

- Plumbing needs to set up the supporting board under the connection port of the tank to avoid unreasonable load and piping load.

- Flash inside of the pipe before connecting with nozzles of the tank to avoid dust while plumbing.

- Use polyvinyl chloride pipes or stainless steel pipes inside of the tank. Do not use carbon-steel and MS pipe.

These kinds of spatter damage the SS Tank Body resulting rust

- Ensure avoiding back-flow for entering pipe (feed water inlet to the tank) such as making enough space between feed water inlet and overflow.

- Avoid any kinds of MS-related work around stainless-steel tank. As MS-particle may penetrate in the Stainless-Steel Tank body and in presence of water, starts rusting so it’s strictly prohibited to conduct any kind of MS-related work nearby SS tank.

- Make sure that any kind of MS structure/MS-tools should not touch and scratch on the SS tank body and galvanized base-frame.

Lists of Instructions and Directions for Use

- Antisepticise and clean up inside of the tank.

- Do not make scratches or cracks by metal tools such as screwdriver and screw wrench.

- Stay flat pressure inside of the tank. Do not make pressure fluctuation inside of the tank by shutting the gable vent and negative pressure.

- There are lists of precautions below for the standard tank with insulation (insulation + aluminum panel t0.8mm)

- Wear the shoes with flats, when you climb to top of the tank for maintenance operation.

- Do not step on the salient of insulation cover which is diamond-cut style.

- Never put the insulations close to fire or heat due to heat-labile material.

- Do not arrange or take off the reinforcement inside of the tank.

- Do not attach any kinds of brackets on the side walls of the tank.

- Do not take off or screw down the assembly bolts for the cradle. Also, do not use the assembly bolts for other parts to assemble.

- If it is necessary to change the content in the tank or there is fluctuation of water level, it would not be suitable for stainless steel panels so contact us and ask.

- When if it is necessary to change the temperature, it is possible to exceed upper temperature limit so contact us and ask.

- Do not put resin product parts close to fire or heat due to heat-labile material.

- Do not move the position of the tank or remake the tank after installation due to water leak.

- Must lock the manhole.

- Built the fence around the tank to keep ‘PRIVATE’.

- Adjust the operating water level within appropriate liquid level for specified stainless steel grade to avoid cause of rust if over the appropriate liquid level.

- If it is going to put the live steam directory, set up silencer to avoid damaging the tank by vibration of the steam.

- Prevent adhesion and/or deposition of foreign matter inside of the tank due to causing corrosion.

- Any kind of remolding work is done on the supplied SS Tank, the warranty clause becomes void.

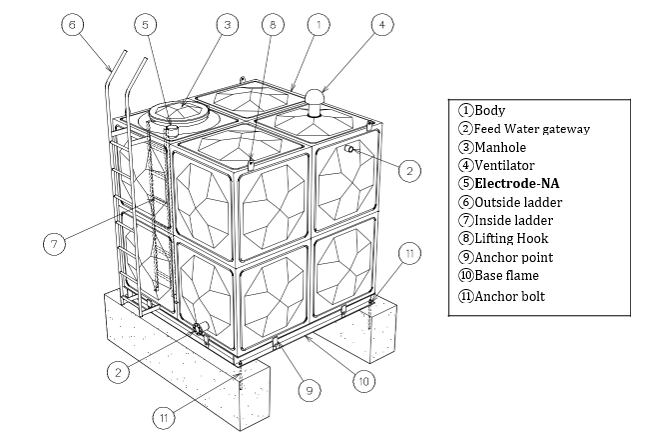

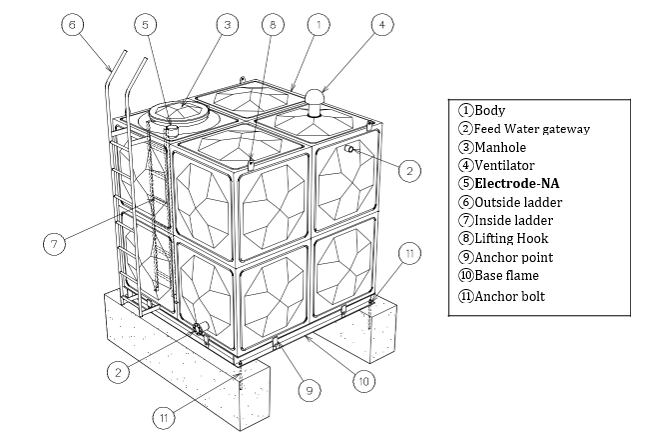

Overview・Standard Parts・Repair Parts

1. Overview

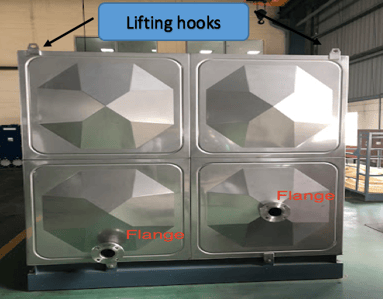

Fig.3-1 Name of Each Tank Part

Standard Parts・Repair Parts

Contact our office, if it is necessary the parts below

Get in touch with us if you looking for an ideal water storage solution for factories and commercial space.

Get in touch with us if you looking for an ideal water storage solution for factories and commercial space.

For more information regarding our stainless steel panel tanks download our product brochure by clicking the button below, drop us your requirement on sales@beltecnoindia.com or call us on any of given numbers +91 9116009580/+91 7300084028

For more Details on Our Product click here

Check our blogs

*https://pubs.spe.org/en/ogf/ogf-article-detail/?art=3566

![]()

Get in touch with us if you looking for an ideal water storage solution for factories and commercial space.

Get in touch with us if you looking for an ideal water storage solution for factories and commercial space.![]()