Importance of stainless steel in a typical dialysis system at hospitals.

Dialysis is one of the processes in medical science where by the use of an artificial kidney, extra fluid and waste can be removed from the blood. During this process blood is removed from the body, filtered and returned to the body with the help of dialysis machine.

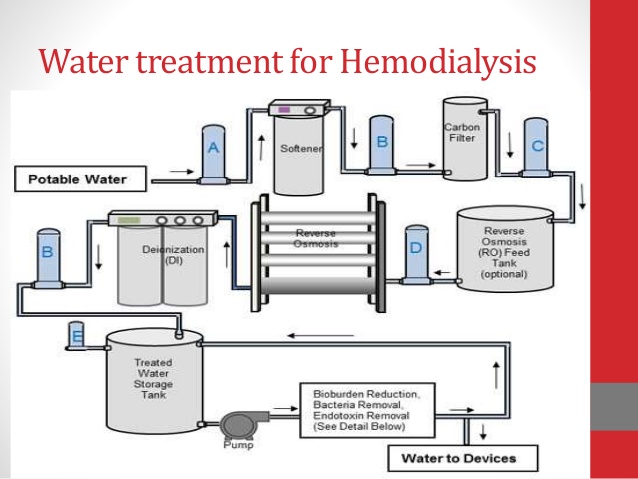

The whole process require a lot of purified water supply and direct feed to dialysis machines to make sure the health and safety of hemodialysis patients. It is vital to ensure the water used to perform dialysis is safe and clean.

Water and dialysis during various stages.

1) Backflow stoppage

Backflow need to be stopped to insure the quality of a potable water system. During this stage a water treatment system reverses flow, the system will divert the treated water to drain insuring the integrity of the potable water feed. Backflow prevention is very important to be installed in a dialysis center.

2) Temperature control Valve

Its must to have a temperature mixing valve to mix the cold and hot incoming water and make to 77 degree F, A RO membrane is most effective if the temperature of incoming feed water is 77 degree F .

3) Water Softener

Water softening is important as it removes positively charged ions (calcium, magnesium, and heavy metals) from the incoming water supply. The main function of a water softener in a dialysis water purification system is to protect and extend the life of the RO membranes. The two styles of water softeners normally used in a dialysis water purification system are: single and duplex softeners.

Source : https://www2.slideshare.net/dialysistechnologist/product-water-and-hemodialysis-dialysis-solution

4) Carbon Filtration Stage

Carbon filtration is a well known method to remove chlorine and low molecular organics through the process. Carbon filtration capacity is commonly sized for the empty bed contact time (EBCT) required to remove chlorine and chloramines from the supply water. AAMI standards for EBCT is 6 minutes for chlorine and 10 minutes for chloramines removal. Carbon beds should be installed in a worker-polisher configuration with test ports installed at the output of both carbon beds. AAMI recommends a test for free and total chlorine is conducted prior to every patient shift.

5) Reverse Osmosis Process

RO has a an important role in dialysis. A RO unit should be equipped with the following:

- 5-micron prefiltration

- Pressure readings

- Flow readings

- Temperature monitor

- Conductivity water quality monitor equipped with visual and audible alarms

Source:https://www.cdc.gov/healthywater/other/medical/hemodialysis.html

6) Water distribution network

During dialysis a continues flow of water is required, there could not be a sudden interruption of supply as it may cause serious problem sometimes. So to make sure an uninterrupted supply of water is required and for that a strong water distribution network indeed. It is responsible to supply purified water from water treatment plant to each dialysis station.

It is highly recommended to use stainless steel as a materials to supply and store dialysis water. PVC and Stainless steel is usually the material of choice for dialysis water distribution systems.

7) Water storage tank

An ideal storage tank should be made of stainless steel. It should have a manhole to access into it for cleaning purpose. Stainless steel due to its properties doesn't allow bacteria formation in side the tank. Its always recommended do check the water quality time to time as its always good to store purified RO water inside stainless steel water tanks.

following are the major reasons why stainless steel water tanks are highly recommended in dialysis water network.

- To provide the best quality water for dialysis

- Emergency bypass in the event of RO failure

- Bacteria control

- Can be installed as makeup tanks in case of emergency.

- Stainless steel panel tanks can be easily insulated to maintain certain temperature.

8) (UV) Ultraviolet Disinfection

UV disinfection is widely used in a dialysis water purification system for bacteria control. its a disinfection method before final stage of filtration and Final filtration should be utilized at the output of the UV disinfection unit.

9) Final Filtration Process

Final Filtration is important because it is recommended for bacteria and endotoxin control. The final filter or ultrafilter should be the last component the purified water passes through before going out to the dialysis stations.

Stainless steel panel tank made by Beltecno used for ICU applications at Batra Hospital, New Delhi

For more information regarding our stainless steel panel tanks download our product brochure by clicking the button below, drop us your requirement on sales@beltecnoindia.com or call us on any of given numbers +91 9116009580/+91 7300084028