Partitioned Rectangle Shape Water Tanks Explained

Do all water tanks do the same job? You might want to think again.

If your facility is running out of space, juggling multiple water types, or dealing with messy maintenance, there’s a smarter way to handle it.

Partitioned rectangular water tanks are changing how modern facilities store and manage water.

Curious how they work and why so many industries are making the switch? Let’s dive in.

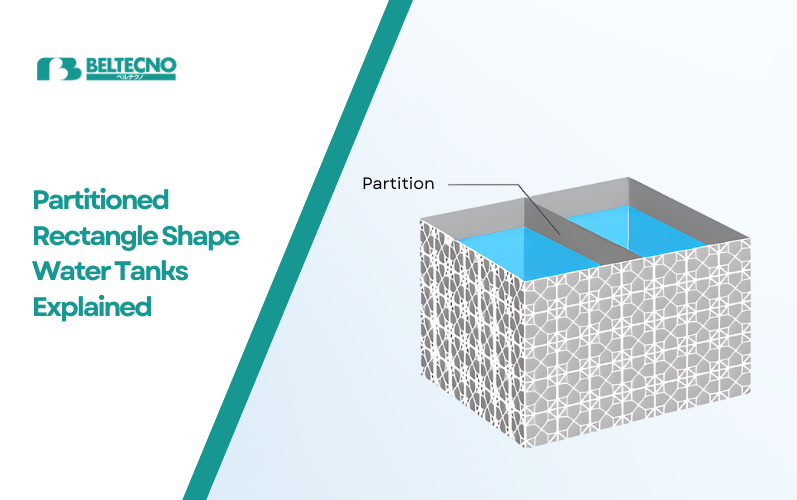

What Exactly is a Rectangle Shape Partitioned Water Tank?

Think of it like this: instead of having one big swimming pool, imagine having a pool divided into separate lanes with solid walls between them. That's essentially what a partitioned water tank does.

These tanks have internal dividers that create completely separate compartments within a single structure. You could be storing drinking water in one section, recycled water in another, and fire protection reserves in a third, all in the same tank, with zero chance of mixing.

The partitions are sealed from floor to ceiling, creating truly independent sections. Modern versions are typically built with advanced stainless steel panels that resist corrosion and keep bacteria at bay. And because they're rectangular, they make incredibly efficient use of space.

Each compartment works independently with its own pipes, inlets, and outlets. It's like having multiple tanks in one, which brings us to why this matters so much.

Why Should You Care? The Real Benefits

-

You'll Save Space and Money

Here's where it gets interesting. Instead of installing three or four separate tanks, each needing its own foundation, plumbing, and space, you build one partitioned system. The footprint shrinks dramatically.

And a smaller footprint means lower costs across the board: less land needed, simpler construction, easier maintenance.

These customised configurations can optimise both your space and your budget in ways traditional tanks simply can't.

-

Keep Different Water Types Separate Without the Hassle

Need to store drinking water and recycled water? No problem. Fire-fighting reserves and process water? Done.

The beauty is that everything stays completely separated and there's zero risk of cross-contamination.

This isn't just convenient, it's often required by regulations. For facilities juggling multiple water streams, this capability is helpful in staying compliant and keeping operations smooth.

-

Never Shut Down Completely

This might be the best part: you can perform maintenance on one compartment while the others keep working. No need to shut down your entire water system.

For hospitals, data centres, or manufacturing plants where downtime isn't an option, this is huge. Drain one section, clean it, repair whatever needs fixing, and your other compartments keep humming along.

-

Better Hygiene, Less Worry

Modern partitioned tanks made with advanced stainless steel are seriously clean. The smooth surfaces don't let bacteria get a foothold, which means less chemical treatment and better water quality overall.

They also resist corrosion, so you're not dealing with rust or material breakdown contaminating your water. If you're storing drinking water, this peace of mind is invaluable.

-

Grow When You Need To

Business expanding? Water needs changing? No worries. You can add partitions or reconfigure existing ones without replacing the entire tank.

This adaptability makes partitioned systems a smart long-term investment. The modular design means you can adjust things down the road without major headaches or shutdowns.

Also, read about the various Features of Stainless Steel Water Tanks

So, What Are The Uses of a Partitioned Tank?

Here's where it gets really interesting. Instead of installing two separate tanks, smart facility managers are asking for a single partitioned panel tank. It's simpler, more efficient, and solves some pretty specific challenges. Let's look at where these are making the biggest impact.

-

Isolating Process Water from Cooling Water or Wastewater

A partitioned tank helps keep process water separate from cooling water or wastewater, which keeps the system clean, stable and easier to manage.

It reduces contamination, improves water quality control and supports smoother operations. This setup also makes maintenance simpler since each section can be inspected or cleaned without interrupting the entire system.

-

Process Tanks in Industrial Applications

You'll find panel tanks in countless industrial process modules, and there's a good reason they're so popular: durability and efficiency.

During manufacturing processes, you often need to store fluids with different consistencies or properties.

You might be dealing with different chemical concentrations, or you need to keep process water separate from cleaning solutions. A partitioned panel tank is one of the most efficient and readily available options on the market.

Instead of managing multiple tanks with different piping systems, you get one robust structure that handles everything. It streamlines the whole process and reduces your maintenance headaches.

-

Commercial and Industrial Water Storage

Of course, panel tanks are also widely used for their original purpose: storing potable water in industries and commercial areas.

Companies like Beltecno are major suppliers of stainless steel panel tanks specifically because they deliver water storage more hygienically.

The stainless steel construction means cleaner water, less maintenance, and longer tank life.

When you need to store drinking water alongside fire protection reserves or other water types, partitioning makes perfect sense.

What You Need to Think About Before Installing

-

Getting the Size Right

You'll want to carefully analyse how much water each type you're storing actually gets used, when demand peaks, and what reserves you need to maintain. Each compartment should handle current needs with room for growth.

Think about daily usage, emergency reserves, and seasonal changes. Getting this right upfront prevents headaches later.

-

Choosing Your Materials

Material choice matters more than you might think. Stainless steel panels with corrosion-resistant properties are increasingly popular because they last longer, stay cleaner, are lightweight, sustainable and need less maintenance.

Consider your water chemistry, the environment where the tank sits, and regulatory requirements. If you're storing drinking water or food-grade process water, you'll need food-grade materials.

-

Making Sure It's Structurally Sound

Partition walls need to handle water pressure from both sides, especially when compartments have different water levels. Proper engineering ensures everything stays stable and watertight for years.

Your foundation has to support the full weight when every compartment is filled. And if you're in earthquake country, seismic design matters too.

-

Planning for Maintenance

Each compartment needs proper access for inspections, cleaning, and repairs. Well-placed manholes and hatches let you do thorough maintenance without entering adjacent compartments.

Think about how equipment might need to get in for future repairs. Good lighting and ventilation are essential for worker safety during inspections.

-

Getting the Plumbing Right

Each compartment needs completely independent piping, inlet, outlet, overflow, and drainage. These systems must never cross-connect.

Add level monitors, pressure sensors, and quality monitoring for each section so you can manage operations effectively. Colour-coded pipes and clear labels prevent confusion during maintenance.

Read about: Customising the Water Tank

FAQ on Partitioned Rectangle Shape Tanks

1. How do partitioned rectangle shape water tanks stop water from mixing between compartments?

Each compartment in a partitioned tank is completely sealed off with solid, watertight walls that run from top to bottom. These walls keep the sections separate, so water from one side never mixes with the other. So you can store different types of water without contamination.

2. What materials are partitioned water tanks made of?

Stainless steel panels are the best for partitioned water tanks. They’re tough, rust-proof and super clean, perfect for keeping water clean and safe. Stainless steel also stops bacteria from growing, making it ideal for drinking water or sensitive water supplies.

3. Can I add more compartments or change the layout later?

Yes! Partitioned panel tanks are modular, so you can add more compartments or change the layout later on. Whether your water needs increase or your setup changes, you don’t have to replace the whole tank, just reconfigure it. It’s a practical, future-proof option.

Conclusion

Partitioned rectangle shape water tanks aren't just the trend; they're genuinely the better way to tackle water storage challenges nowadays.

By letting you store multiple types of water within one piece of kit, these systems bring some real advantages to the table.

You can fit more storage into a smaller space, manage your water needs more flexibly & come out with a lower overall cost compared to traditional & separate single-purpose tanks.

If you're either upgrading an existing facility or working on a brand new build, it's worth considering the rectangular partitioned water tanks.

Want to see where one could help with your specific water management needs? Contact us today to get a tailored solution that makes sense for your project.