Water for industrial use - Part 2 (Industrial Water Series)

What kind of water must be used for industrial purposes

For almost every manufacturer, starting a manufacturing business is the next step in growth. There are many aspects to think about, when starting a new manufacturing company. Safety issues will also arise in any processes where there can be danger to life, such as refineries.

1) Ultrapure water use in semiconductor manufacturing

Silicon is one of the most important materials used in the manufacture of computer hardware, cell phones, and automobiles. Pure silicon cannot be manufactured without ultra pure water. Plus, there are a number of chemical processes that require an inert atmosphere to prevent contamination.

![]()

For example, during the production of semiconductors, the industry uses massive quantities of very high purity (99.9999999%) nitrogen gas. Nitrogen is also used for cleaning equipment and as a carrier gas in chromatography.

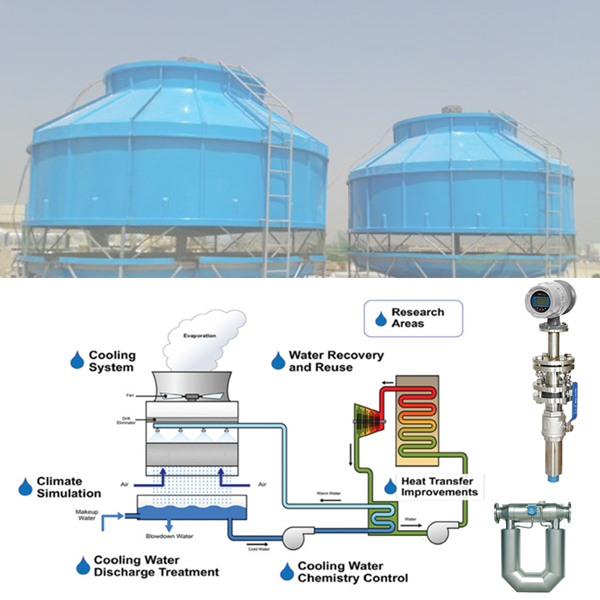

2) Cooling water

A cooling system transfers the energy of hot objects into cold ones by transferring the energy of hot objects to coolers. The main purpose of a cooling system is to take away the energy of hot objects and transfer it to colder objects. Most cooling systems use water as the working fluid because it has high thermal conductivity. The difference in temperature between the hot object and the cooler is usually in the range of 10–200°F (5–93°C).

Water has many properties, including its ability to dissolve solids, absorb gases, conduct electricity, and so on. These properties are influenced by the water’s physical state (e.g., liquid vs solid), which in turn depends on the water’s chemical composition (i.e., the presence of dissolved substances). For example, when water freezes, some of its properties change dramatically.

3) Water use in the oil & gas markets

Globally, the energysectoraccountsforjustunder5percent of globalwithdrawals, but has an important part to playing in ensuring the safety of ourdrinking water supplies. Water is a raw materials used and produced in largeamountsby the energysector, from extraction activities through refining and petrochemicals production.

It can be used for injection, processing, producing, treating, recycling, purifying, washing, cleaning, drinking, and others.

4) Water use in pulp & paper mills

Despite the fact that digitalization has prompted a shift towards online shopping, the printing industry continues to be one of the biggest consumers of water globally. Water is intimately linked with 85% of all the three stages involved in the manufacture of papers including pulping, bleaching, and wash. A high quantity of water consumed in the pulp and paper industry is used only for processing, thus, leading to the generation of large volumes of contaminated wastewater.

Percentage of water is used for industrial purposes

Without water, most companies and the things they produce would not exist. Water is essential for almost every step of the manufacture and processing of goods around the globe. Whether it’s deionized water for electronic and pharma industries, or softened water for boiler feed applications; water is an integral part of everything we create.

Industrial waste is responsible for approximately 40% of total fresh-to-sea abstraction. At the same time, many large global corporations operate in regions where there is limited access to clean drinking and irrigation waters. We tried to provides an essential overview of everything you need to know regarding industrial waste water management.

WHY Beltecno for Water Tanks for storage of thermal energy ?

We have been manufacturing stainless steel panel tanks since 1947 and pride ourselves on providing top-quality water tanks made of stainless steel at affordable prices globally.

Stainless steel is extremely durable, meaning that it won't crack or break easily. This makes them ideal for businesses that deal with large amounts of liquid, such as breweries, wineries, and distilleries.

Stainless steel tanks don't corrode over time, unlike Iron and FRP tanks. This means that they can last longer than other types of tanks, potentially saving money down the road.

For more information regarding our stainless steel panel tanks download our product brochure by clicking the button below, drop us your requirement on sales@beltecnoindia.com or call us on any of given numbers +91 9116009580/+91 7300084028