A Complete Guide to Water Tank Material & Grades

Did you know that not all stainless steel is safe for water storage? When researching industrial water storage tanks, you’ll often find stainless steel ranked as the best material. And rightly so, stainless steel tanks are hygienic, durable, corrosion-resistant, and widely used across industries such as food processing, pharmaceuticals, water treatment plants, and data centres.

But here’s the catch: not all stainless steel grades are created equal. Choosing the wrong grade can lead to corrosion, contamination, reduced lifespan, and unexpected maintenance costs. So, how about the stainless steel grade is right for your application?

Don’t worry, this blog is your complete guide to stainless steel water tank material grades, their properties, applications, and how to select the best one for your industry.

Let’s dive in.

Why Stainless Steel Is Preferred for Industrial Water Storage Tanks

Before we compare grades, it’s important to understand why stainless steel is widely used by leading water tank manufacturers:

- Non-reactive and hygienic surface

- Resistant to corrosion, rust, and microbial growth

- Long service life with minimal maintenance

- 100% recyclable and environmentally friendly

- Suitable for potable, RO, and process water

However, the performance of a stainless steel water tank depends heavily on the grade used.

Common Stainless Steel Grades Used in Water Tanks

Water tank manufacturers use different stainless steel grades based on application, water chemistry, and environmental conditions. Below are the most commonly used stainless steel grades in water tanks and their key characteristics.

1. SS304 Stainless Steel Grade

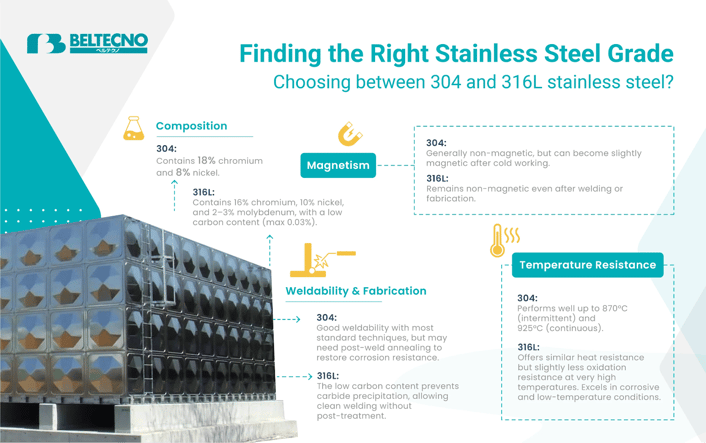

SS304 is the most commonly used austenitic stainless steel grade for water storage tanks. It contains approximately 18% chromium and 8% nickel, which gives it excellent corrosion resistance and structural stability.

Key characteristics:

- Good resistance to rust and oxidation

- Excellent formability and weldability

- Performs well in water, food, and mild chemical environments

- Non-reactive and hygienic

SS304 resists oxidation up to 870°C, making it suitable for both indoor and outdoor installations in non-aggressive environments.

Typical applications:

- Drinking water storage tanks

- Food and beverage processing

- Commercial and residential water tanks

- Architectural and utility tanks

Affordable, reliable, and easy to maintain, SS304 is the go-to choice for general-purpose industrial water storage tanks.

2. SS316 / SS316L Stainless Steel Grade

SS316 and SS316L are premium grades designed for more demanding environments.

Both contain molybdenum, which significantly improves resistance to corrosion caused by chlorides, salts, and acidic substances.

So what’s the difference between SS316 and SS316L?

- SS316: Maximum carbon content of 0.08%

- SS316L: Lower carbon content (max 0.03%)

The reduced carbon content in SS316L minimises carbide precipitation during welding, preventing intergranular corrosion and making it ideal for sanitary applications.

Key advantages:

- Superior resistance to chlorides and chemicals

- Excellent weldability (especially SS316L)

- Long lifespan in harsh environments

Common applications:

- RO and DM water storage

- Pharmaceutical and biotech industries

- Marine and coastal installations

- Food processing plants

Beltecno stainless steel water tanks are manufactured using SS304 and SS316L, ensuring compliance with hygiene, durability, and performance standards.

3. Duplex Stainless Steel

Duplex stainless steel is a high-performance alloy combining the best properties of austenitic and ferritic stainless steels.

It offers:

- Extremely high strength

- Superior resistance to stress corrosion cracking

- Excellent performance in aggressive environments

One of its biggest advantages is its high strength-to-weight ratio, allowing thinner walls without compromising durability.

Best suited for:

- Chemical storage tanks

- Desalination plants

- Offshore and marine applications

- High-pressure industrial environments

While duplex stainless steel offers exceptional durability, it is more expensive and complex to fabricate, making it suitable only where extreme performance is required.

4. SS430 Stainless Steel Grade

SS430 is a ferritic stainless steel, meaning it contains iron and chromium but little to no nickel.

Key traits:

- Magnetic in nature

- Lower cost than SS304 and SS316

- Moderate corrosion resistance

However, SS430 lacks the durability and corrosion resistance required for industrial water storage tanks exposed to moisture, chemicals, or outdoor conditions.

Suitable for:

- Decorative water tanks

- Indoor, low-humidity applications

- Non-critical or aesthetic installations

It is not recommended for potable water or industrial use due to limited weldability and corrosion resistance.

Comparison of Stainless Steel Grades for Water Tanks

To help you quickly evaluate which stainless steel grade best suits your application, the table below compares key properties such as corrosion resistance, cost, lifespan, and weldability across commonly used water tank materials.

|

Property |

SS304 |

SS316 / 316L |

Duplex SS |

SS430 |

|

Corrosion Resistance |

Good |

Excellent |

Superior |

Fair |

|

Heat Resistance |

High |

Very High |

Very High |

Moderate |

|

Cost |

Moderate |

High |

High |

Low |

|

Maintenance |

Low |

Low |

Medium |

Medium |

|

Lifespan |

10–15 yrs |

15–25 yrs |

25+ yrs |

<10 yrs |

|

Magnetic |

Non-magnetic |

Non-magnetic |

Slightly magnetic |

Magnetic |

|

Weldability |

Excellent |

Excellent (316L best) |

Good |

Poor |

|

Formability |

Excellent |

Excellent |

Moderate |

Good |

Industry-Wise Stainless Steel Grade Suitability

Different industries operate under varying environmental, hygiene, and regulatory conditions. Choosing the right stainless steel grade depends on how and where the water tank will be used. Below is an industry-wise breakdown to help you identify the most suitable grade for each application.

Food & Beverage Industry

Hygiene, safety, and compliance are critical in this sector.

Recommended grades:

- SS304 (standard environments)

- SS316 (acidic or high-salt processes)

These grades:

- Are food-grade certified

- Do not leach chemicals

- Maintain taste and purity

SS430 lacks hygienic properties, while duplex steel is unnecessary and costly.

Read more: Stainless steel applications in the Food & Beverage Industry

Pharmaceutical Industry

Pharmaceutical manufacturing demands ultra-clean and sterile storage.

Best choice: SS316L

Why?

- Low carbon content reduces contamination risk.

- Excellent resistance to aggressive cleaning agents

- Compliant with pharmaceutical hygiene standards

Duplex steel is unnecessary, and SS430 may fail prematurely.

Case study: Stainless Steel Application in the Healthcare Industry

Water Treatment Plants

Water chemistry and environment determine the grade selection.

- SS304: Ideal for potable water and standard treatment plants

- SS316L: Recommended for coastal or high-chloride environments

- Duplex SS: Used in desalination and highly aggressive water conditions

SS430 is unsuitable due to insufficient corrosion resistance.

Data Centres

Reliability and longevity are key.

- SS304: Suitable for indoor, controlled environments

- SS316L: Best for coastal regions or treated water storage

Duplex steel is unnecessary, and SS430 may fail prematurely.

Read more: Stainless Steel Application in Data Centres

Best Material For Water Tank: Choosing the Right Stainless Steel Grade

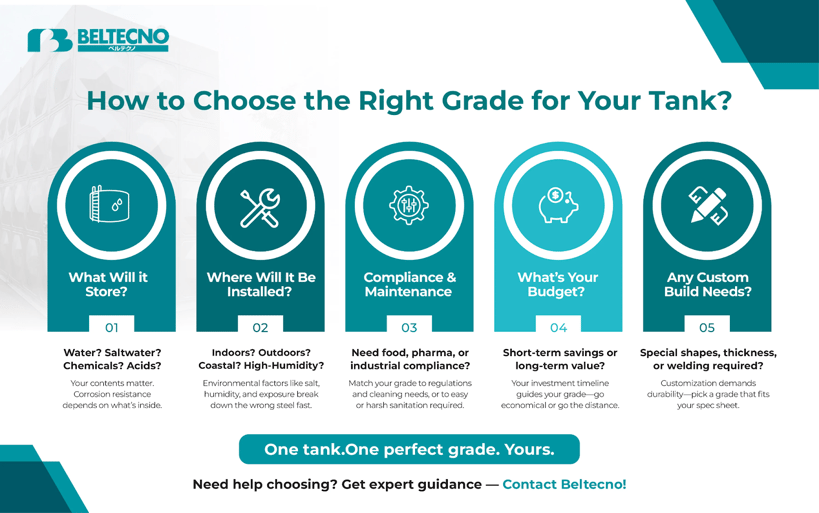

Before finalising your tank material, consider the following:

- Assess the Stored Content – Water type, chemicals, or corrosive media

- Understand the Environment – Indoor, outdoor, coastal, or humid

- Budget vs Lifecycle Cost – Initial cost vs long-term durability

- Regulatory Compliance – Food-grade or pharma-grade requirements

- Maintenance Capabilities – Cleaning frequency and access

- Customisation Needs – Size, fittings, insulation, or compartments

Leading water storage tank manufacturers like Beltecno offer customised stainless steel tanks tailored to your industry's needs.

FAQs on Stainless Steel Water Tank Grades

Q1: Can SS304 be used for drinking water?

Q1: Can SS304 be used for drinking water?

Q2: What’s the difference between SS316 and SS316L?

SS316L has lower carbon content, improving weldability and corrosion resistance at joints.

Q3: Is SS430 safe for water tanks?

Only for low-risk, indoor, non-critical applications. Not recommended for long-term use.

Q4: Which grade lasts longest in coastal environments?

SS316L and Duplex stainless steel perform best in salt-laden air.

Q5: Can different grades be mixed in one tank?

Not recommended, as it may cause galvanic corrosion and reduce tank lifespan.

Choosing the right stainless steel grade is critical to the performance, safety, and lifespan of industrial water storage tanks.

Whether you need:

- SS304 for general-purpose use

- SS316L for harsh or sanitary environments

- Duplex stainless steel for extreme conditions

Each grade serves a specific purpose.

If you’re unsure which material suits your application, Beltecno’s experts are here to help. As one of the trusted water tank manufacturers, Beltecno delivers custom-engineered stainless steel tanks that are reliable, compliant, and provide long-term value.

Contact Beltecno today for expert guidance and tailored water storage solutions you can trust.